RemoteGen® ~ The Intelligent Control System for CHP plants

Our RemoteGen® system monitors the exhaust temperature for each individual cylinder. The temperatures are compared with each other. If a cylinder deviates from a characteristic curve, the immediate stop of the current generator takes place. This monitoring system ensures long-term operation of your power generator and detects costly disturbances of individual cylinders at an early stage.

Our RemoteGen® system is available in 3 stages:

1.) Exhaust gas temperature monitoring with immediate shutdown of the unit RemoteGen®

2.) Monitoring of all important parameters on the Internet or on a local PC RemoteGenDia®

3.) Module for the diagnosis and recording of all important parameters RemoteGenWeb®

1.) Exhaust gas temperature monitoring with immediate shutdown of the unit

Exhaust gas temperature monitoring for each individual cylinder consisting of 6/8/10/12 channel temperature measurement. The temperature measurement values are evaluated with the help of the TwinCAT® PLC control. The system is installed in a terminal box with sight glass. The intelligent terminal box is installed in the immediate vicinity of the MAN drive motor. The terminal box transmits all important signals via MODbus to the generator control.

2.) Monitoring of all important parameters on the Internet or on a local PC

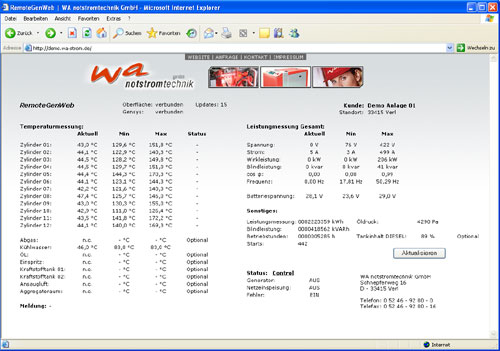

The optional monitoring module enables the monitoring of the aggregate and monitoring of all important aggregate states via an Ethernet TCP / IP interface. This interface can be connected directly to the Internet via router and DSL. With a browser e.g. Internet Explorer, you can log in to your system worldwide and monitor the values. It is also possible to connect a local PC or an intranet to this interface.

(Available only in conjunction with item 1.)

– RemoteGen® Frontend via Internet Explorer –

3.) RemoteGenDia®, module for diagnosis and recording of all important parameters

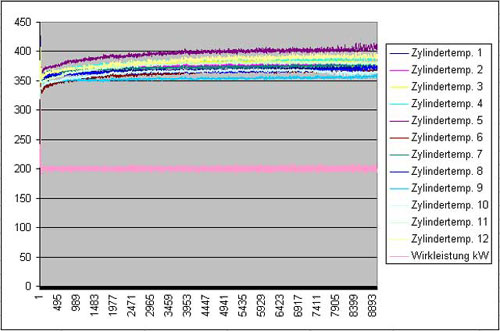

This optional module is installed on a local PC which communicates with the TwinCAT® PLC control via a network connection (Ethernet TCP / IP interface). All important aggregate states are logged and written into a CSV file (semicolon, separate file). This file can be evaluated with a spreadsheet program (e.g., Microsoft Exel). With these evaluations, you have the possibility to create a complete history of the aggregate. For recording, it is necessary that the local PC is permanently connected to the system.

(Available only in conjunction with items 1 & 2.)

– example of the RemoteGenDia® recording in normal operation of the aggregate-

– Here you can see the temperatures of the cylinders and the actual power in KW

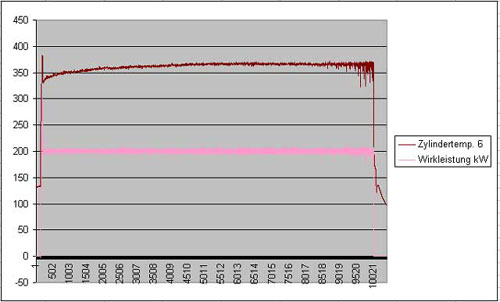

The aggregate was stopped during the strong fluctuations of the cylinder temperature. This case describes the classical defect in the vegetable oil operation of an injection nozzle, here after 2,500 hours on cylinder 6.

Further information about combined heat and power plants: